Afr Air Flow Research is a crucial aspect of engine performance and efficiency. It encompasses the study of how air moves through an engine and the factors that influence its movement. This research area plays a vital role in optimizing engine design, improving fuel efficiency, and reducing emissions. In this comprehensive guide, we delve into the intricacies of AFR air flow research, exploring its significance, key principles, and applications.

Understanding AFR Air Flow Research: The Basics

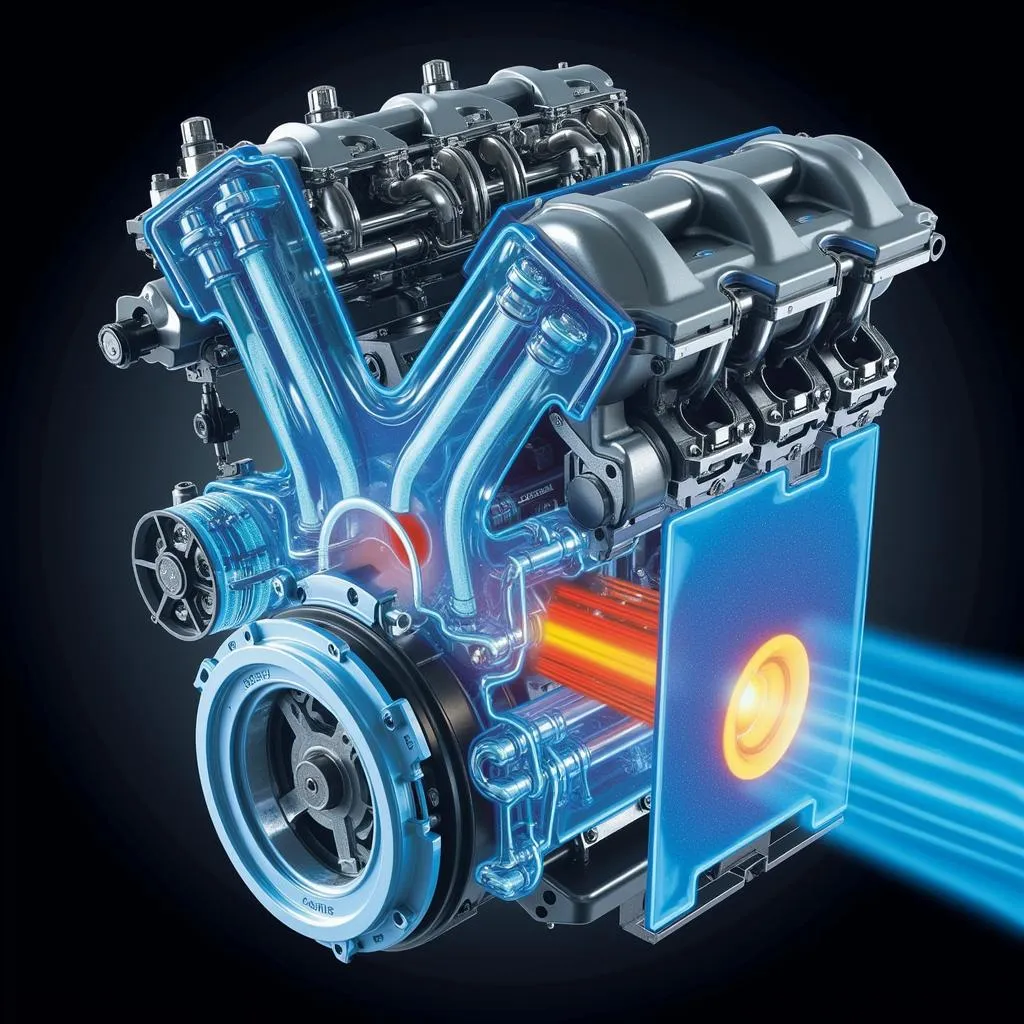

AFR Air Flow Research focuses on the analysis and manipulation of airflow within engines. It’s a multidisciplinary field that integrates principles from fluid mechanics, thermodynamics, and combustion science. By understanding the complex interplay of factors like pressure, temperature, velocity, and density, researchers can optimize engine performance and fuel efficiency.

The Importance of Air Flow Research

Imagine a car engine as a breathing machine. It needs a constant supply of air to burn fuel effectively. AFR Air Flow Research aims to ensure this air intake is efficient and optimized. Here’s why this is critical:

- Fuel Efficiency: Optimal airflow allows the engine to burn fuel more completely, reducing waste and improving fuel economy.

- Power Output: Proper airflow ensures sufficient oxygen for combustion, leading to increased power output.

- Emissions Reduction: Efficient combustion reduces harmful emissions such as carbon monoxide, hydrocarbons, and particulate matter.

- Engine Durability: Optimized airflow minimizes stress on engine components, extending their lifespan.

Key Concepts in AFR Air Flow Research

To understand AFR Air Flow Research, it’s essential to grasp some fundamental concepts:

- Aerodynamics: This branch of physics deals with the flow of air and its effects on objects. Aerodynamic principles guide the design of engine components like air inlets, exhaust systems, and valve configurations.

- Turbulence: Airflow can be smooth or turbulent, with turbulence leading to energy loss and reduced efficiency. Research focuses on minimizing turbulence within engines.

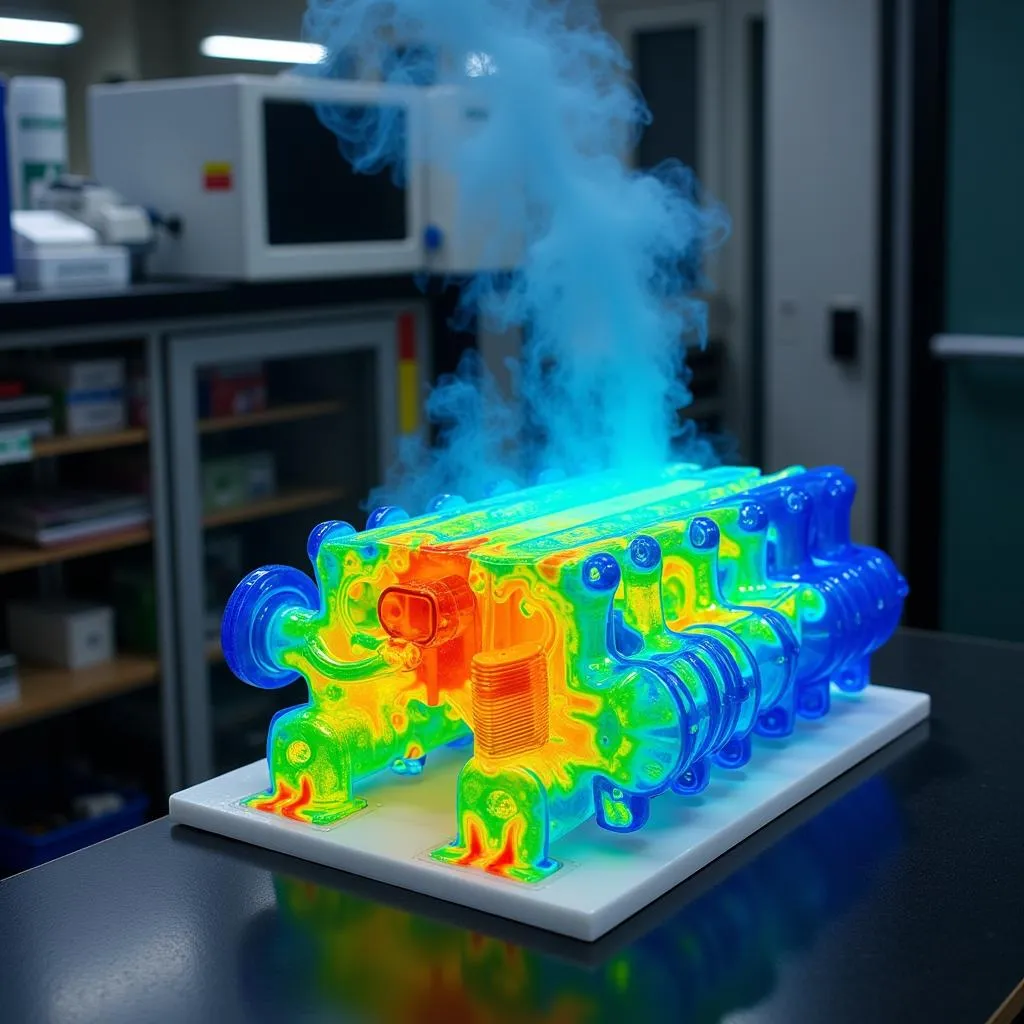

- Flow Visualization: Techniques like smoke visualization and particle image velocimetry help researchers visualize airflow patterns, enabling them to identify bottlenecks and optimize flow paths.

- Computational Fluid Dynamics (CFD): CFD simulations use mathematical models to analyze airflow behavior within complex geometries. This technology allows researchers to test various design iterations virtually, reducing the need for costly physical prototypes.

Applications of AFR Air Flow Research

The insights gleaned from AFR Air Flow Research have numerous practical applications, revolutionizing engine design and optimization across various industries:

- Automotive: AFR Air Flow Research drives advancements in engine efficiency and emission control, contributing to fuel-saving vehicles and reduced environmental impact.

- Aerospace: Optimizing airflow is crucial for aircraft propulsion systems, increasing efficiency and fuel economy.

- Power Generation: Understanding airflow dynamics is essential for designing efficient turbines and combustion chambers in power plants.

- Industrial Equipment: Many industrial processes rely on efficient air flow, making AFR Air Flow Research vital for optimizing equipment performance and minimizing energy consumption.

The Future of AFR Air Flow Research

Research in this field continues to evolve, driven by advancements in computational tools, data analysis, and experimental techniques. Here are some key areas of future focus:

- Hybrid and Electric Propulsion Systems: As the automotive industry transitions to electric vehicles and hybrid powertrains, research will focus on optimizing air flow for electric motors and hybrid systems.

- Advanced Materials and Design: The use of lightweight and advanced materials in engine design presents new challenges and opportunities for AFR Air Flow Research.

- Data Analytics and Machine Learning: Big data and machine learning algorithms are revolutionizing engine optimization. By analyzing vast amounts of data generated from sensors and simulations, researchers can identify complex patterns and optimize airflow in real-time.

Frequently Asked Questions

Q1: How does AFR Air Flow Research influence fuel efficiency?

A1: AFR Air Flow Research ensures the engine receives the optimal amount of air for complete fuel combustion. This minimizes fuel waste and improves fuel economy.

Q2: What are the benefits of using CFD for AFR Air Flow Research?

A2: CFD allows researchers to test various design iterations virtually, reducing the cost and time associated with physical prototypes. It also provides detailed insights into airflow patterns, enabling optimization of engine performance.

Q3: How can I learn more about AFR Air Flow Research?

A3: You can access a wealth of information through online resources, academic journals, and industry conferences specializing in engine technology and fluid mechanics.

Q4: Can AFR Air Flow Research be used to reduce engine noise?

A4: Yes, understanding airflow patterns and turbulence helps engineers design engine components that minimize noise generation.

Q5: Is AFR Air Flow Research relevant to environmental sustainability?

A5: Absolutely! Optimizing airflow leads to more efficient combustion, reducing harmful emissions and contributing to a cleaner environment.

AFR Air Flow Research: Optimizing Engine Performance

AFR Air Flow Research: Optimizing Engine Performance

Visualizing Airflow Patterns for Improved Engine Design

Visualizing Airflow Patterns for Improved Engine Design

Conclusion

AFR Air Flow Research plays a pivotal role in optimizing engine performance, fuel efficiency, and emission control. By delving into the intricate dynamics of airflow, researchers unlock valuable insights that drive innovation across various industries. As the field continues to evolve, we can expect even greater advancements in engine technology, contributing to a more sustainable and efficient future.