The enigmatic world of Advanced Casting Research Centers often sparks curiosity and intrigue. These hubs of innovation push the boundaries of material science, exploring new techniques and applications for casting processes. What exactly goes on within these specialized facilities? Let’s delve into the fascinating realm of advanced casting research.

Inside an Advanced Casting Research Center: A Glimpse into the Future of Materials

Advanced casting research centers are more than just laboratories; they are the birthplace of next-generation materials. Researchers within these centers tackle complex challenges, seeking to improve existing casting methods and pioneer entirely new approaches. Their work impacts a diverse range of industries, from aerospace and automotive to biomedical and energy. One area of focus is the development of lighter, stronger, and more durable materials. This involves experimenting with novel alloys and composites, pushing the limits of material performance.

The university corporation for atmospheric research conducts research that, while not directly related to casting, shares a similar focus on advanced materials and their properties.

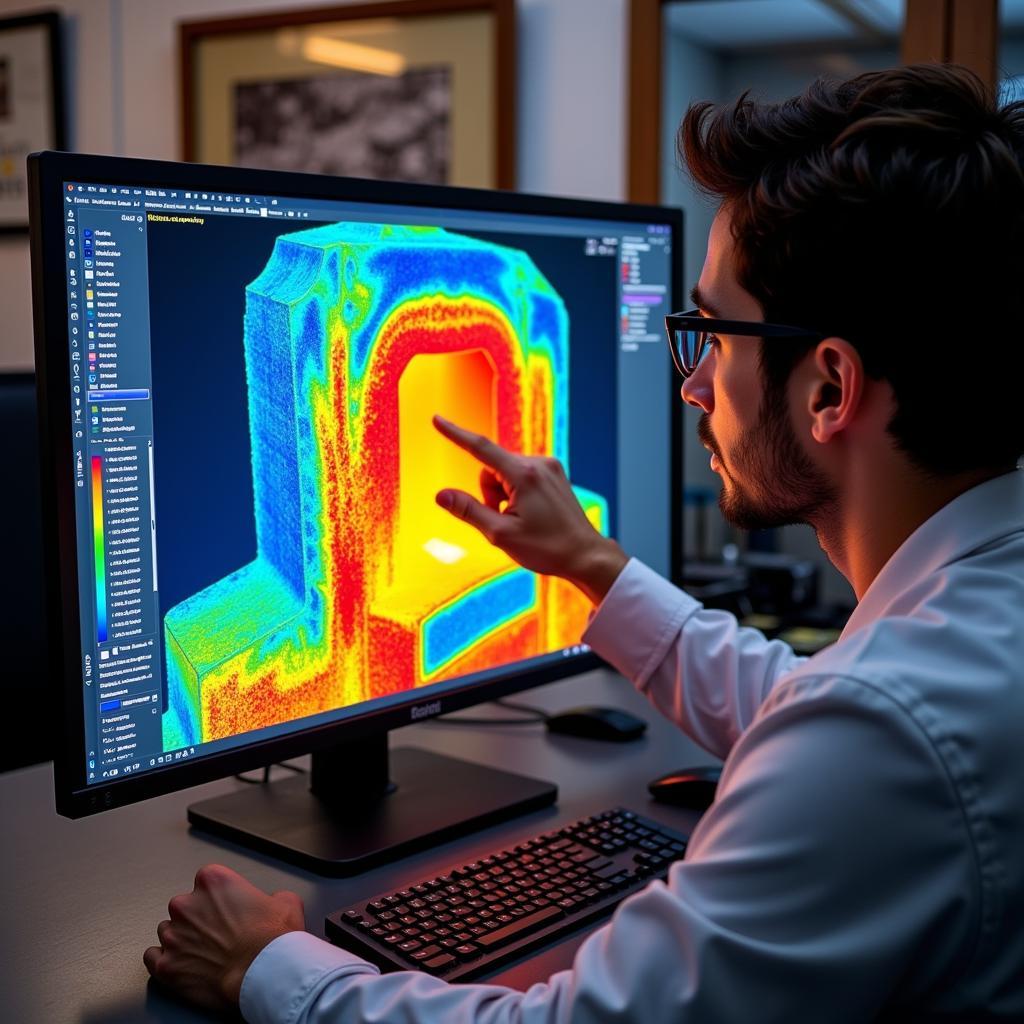

Another key area of exploration is the refinement of casting processes themselves. Researchers are constantly seeking ways to improve precision, reduce defects, and enhance the overall efficiency of casting operations. This includes developing sophisticated simulation software to model and predict the behavior of molten metal during the casting process, allowing for optimization and troubleshooting before physical prototypes are even created.

Advanced Casting Research Center Simulation Software in Action

Advanced Casting Research Center Simulation Software in Action

Exploring the Cutting-Edge Technologies Used in Advanced Casting Research

Advanced casting research centers employ a range of cutting-edge technologies to achieve their goals. High-speed cameras capture the intricate dynamics of the casting process in milliseconds, allowing researchers to analyze every detail of the molten metal flow. Powerful microscopes reveal the microstructural features of the solidified castings, providing insights into the relationship between processing parameters and material properties. Furthermore, 3D printing technology is increasingly being utilized to create intricate molds and prototypes with unprecedented speed and accuracy.

What kinds of research are conducted at these centers? Research encompasses everything from developing new alloys for high-temperature applications to optimizing the casting process for complex geometries. This involves a multidisciplinary approach, drawing upon expertise in metallurgy, materials science, mechanical engineering, and computer simulation.

The aerospace information research institute often utilizes similar advanced technologies in their research endeavors.

The Impact of Advanced Casting Research on Various Industries

The innovations emerging from advanced casting research centers have far-reaching implications for various industries. In the automotive sector, lighter and stronger castings contribute to improved fuel efficiency and vehicle performance. In aerospace, advanced casting techniques enable the creation of complex components for jet engines and spacecraft. The biomedical industry benefits from the development of biocompatible implants and prosthetics. The energy sector utilizes advanced castings in the production of turbines and other critical components.

How do these centers contribute to advancements in casting technology? They serve as incubators for groundbreaking research, fostering collaboration between academia and industry. This collaborative environment accelerates the development and implementation of new casting technologies, pushing the boundaries of what’s possible.

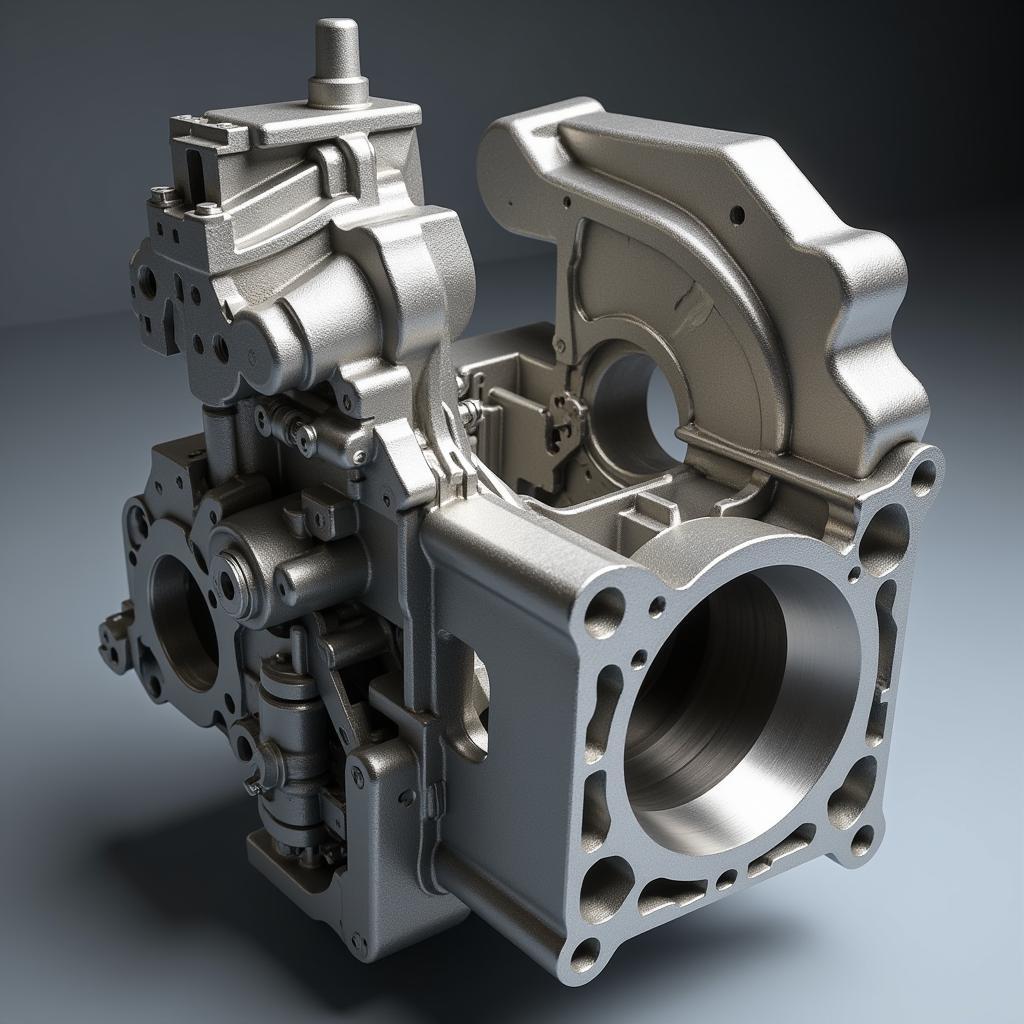

Advanced Casting Application in Automotive Engine Component

Advanced Casting Application in Automotive Engine Component

The hudson research partners and the atmospheric sciences research center also contribute to advancements in their respective fields, albeit with different focuses.

Conclusion: Shaping the Future of Materials Through Advanced Casting Research

Advanced casting research centers play a pivotal role in shaping the future of materials. Their tireless efforts to improve and innovate casting technologies have a profound impact on a multitude of industries, driving progress and enabling the creation of products that were once unimaginable. As we continue to push the boundaries of material science, these centers will remain at the forefront of discovery, unlocking new possibilities and transforming the world around us.

FAQ

- What is the primary goal of an advanced casting research center?

- What types of industries benefit from advanced casting research?

- What are some examples of cutting-edge technologies used in these centers?

- How does advanced casting research contribute to sustainability?

- What are the career opportunities in advanced casting research?

- How can I get involved in advanced casting research?

- What is the future of advanced casting research?

Common Scenarios and Questions

Scenario: A manufacturer is looking to improve the durability of a critical component.

Question: How can an advanced casting research center help them achieve this goal?

Scenario: A researcher is interested in developing a new alloy with specific properties.

Question: What resources and expertise are available at an advanced casting research center to support their research?

Further Exploration

For more information on related topics, explore these other articles on our website: University Corporation for Atmospheric Research, Aerospace Information Research Institute

Need Assistance?

For inquiries or support, please contact us: Phone: 0904826292, Email: research@gmail.com or visit our address: No. 31, Alley 142/7, P. Phú Viên, Bồ Đề, Long Biên, Hà Nội, Việt Nam. We have a 24/7 customer service team available to assist you.