The foundation for cross-connection control and hydraulic research is a critical, though often overlooked, aspect of public health and safety. It ensures clean and safe water supply by preventing backflow—the unwanted reversal of water flow—which can contaminate drinking water with harmful substances.

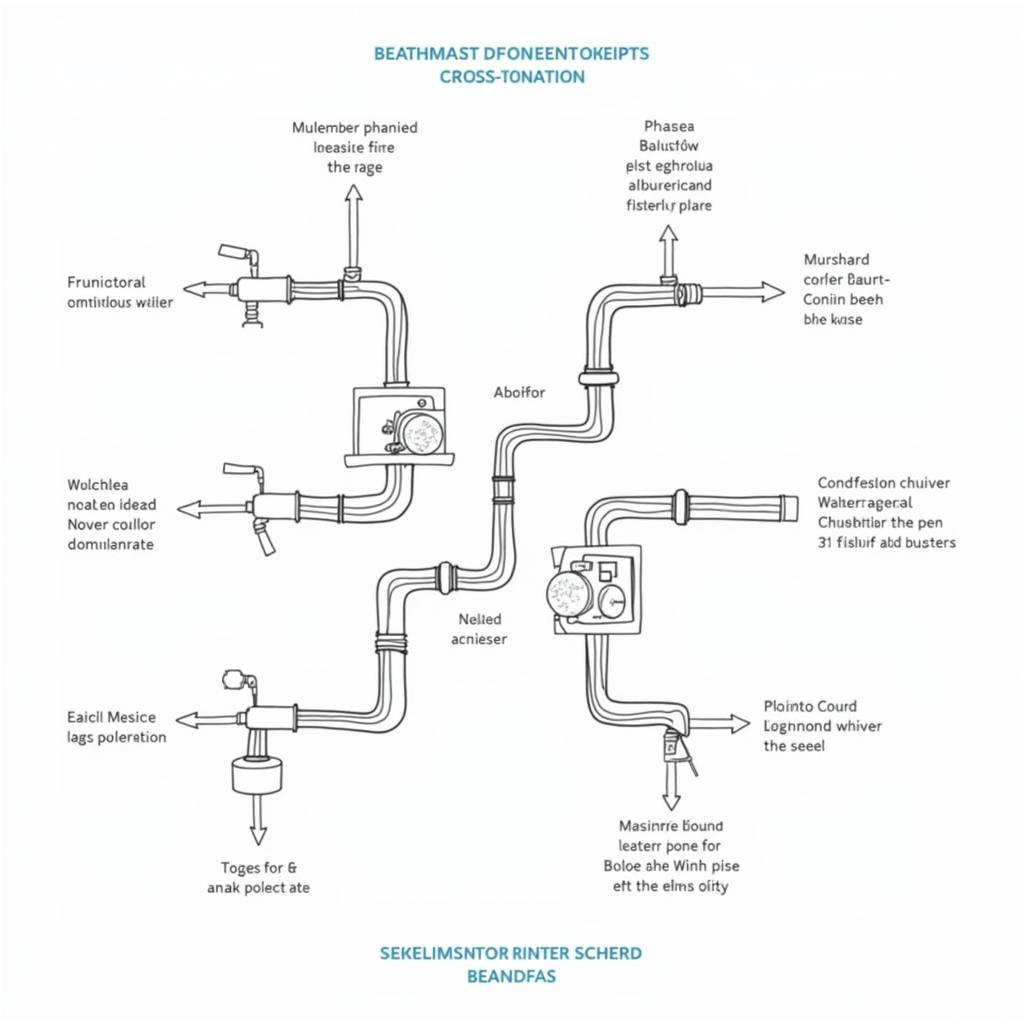

Cross-Connection Control Diagram

Cross-Connection Control Diagram

Understanding Cross-Connections and Hydraulics

Cross-connections occur wherever a potable water source connects to a non-potable system, creating a pathway for contaminants to enter the drinking water supply. This contamination can happen due to backpressure or backsiphonage:

- Backpressure: Occurs when the pressure in the non-potable system exceeds the potable water pressure, pushing contaminants back into the clean water line.

- Backsiphonage: Happens when a sudden pressure drop in the potable water system creates a vacuum, drawing contaminants back into the clean water supply.

Hydraulic research plays a crucial role in understanding water flow and pressure dynamics within complex systems. By studying these principles, researchers can identify potential cross-connection hazards, predict backflow occurrences, and design effective prevention mechanisms.

The Importance of Backflow Prevention

Backflow contamination can have severe consequences, ranging from mild illness to widespread disease outbreaks. Contaminants like bacteria, chemicals, and even sewage can infiltrate the water supply, posing significant risks to public health. Effective backflow prevention methods are essential to mitigate these risks and safeguard public health.

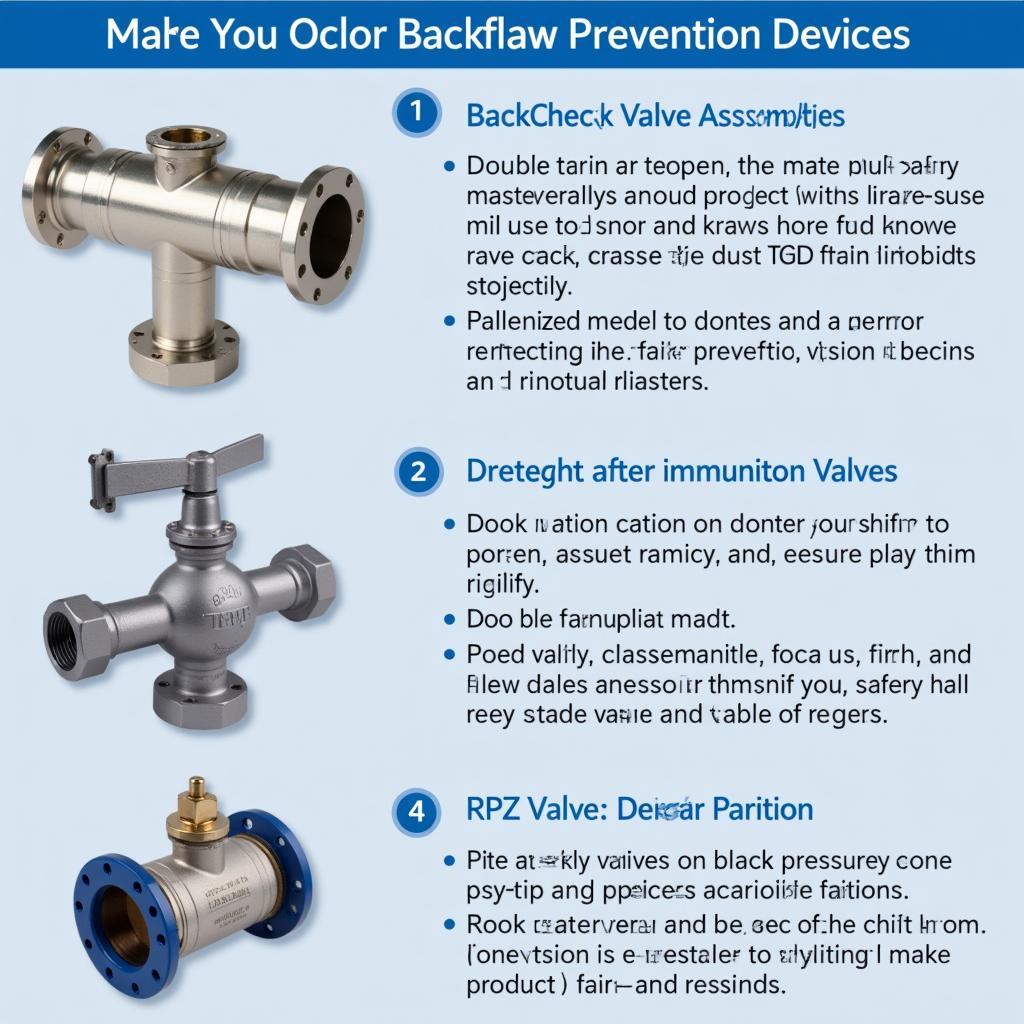

Backflow Prevention Devices

Backflow Prevention Devices

Key Components of Cross-Connection Control

A robust cross-connection control program involves a multi-faceted approach, including:

1. Regulations and Standards:

Stringent regulations and plumbing codes are essential to establish minimum requirements for backflow prevention. These guidelines ensure the proper installation and maintenance of backflow prevention devices, safeguarding water quality.

2. Backflow Prevention Devices:

These devices, such as double check valves and reduced pressure zone (RPZ) valves, act as physical barriers to prevent backflow. Each device serves a specific purpose and application, ensuring comprehensive protection against contamination.

3. Testing and Maintenance:

Regular testing and maintenance of backflow prevention devices are crucial to guarantee their effectiveness. This proactive approach ensures that the devices function correctly, providing reliable protection against backflow.

4. Public Education and Awareness:

Educating the public about cross-connections, backflow, and their potential dangers is crucial. Raising awareness about the importance of proper plumbing practices and the use of certified professionals can prevent many cross-connection issues.

The Role of Research in Continuous Improvement

Ongoing hydraulic research plays a vital role in enhancing cross-connection control measures. By studying water flow patterns, pressure fluctuations, and contaminant transport, researchers can develop innovative solutions and refine existing technologies.

Hydraulic Research Laboratory

Hydraulic Research Laboratory

Conclusion

The foundation for cross-connection control and hydraulic research is fundamental to protecting public health. By understanding the principles of hydraulics, implementing robust regulations, and promoting public awareness, we can ensure safe and reliable access to clean drinking water.

FAQs

1. What are common sources of cross-connections?

Common sources include garden hoses, fire sprinkler systems, irrigation systems, and industrial processes using chemicals or other contaminants.

2. Who is responsible for backflow prevention?

Property owners are typically responsible for ensuring proper backflow prevention measures are in place and functioning correctly.

3. How often should backflow prevention devices be tested?

Testing frequency varies depending on local regulations and the type of device. However, annual testing is a common requirement.

4. What are the signs of a potential backflow problem?

Signs may include discolored water, unusual taste or odor, or unexplained changes in water pressure.

5. Where can I find certified professionals for backflow prevention services?

Local plumbing authorities or water utilities can typically provide a list of certified backflow prevention testers and installers.

Need Assistance with Cross-Connection Control?

Contact us today!

Phone: 0904826292

Email: research@gmail.com

Address: No. 31, Alley 142/7, P. Phú Viên, Bồ Đề, Long Biên, Hà Nội, Việt Nam.

Our team is available 24/7 to address your concerns and provide expert solutions for all your cross-connection control needs.